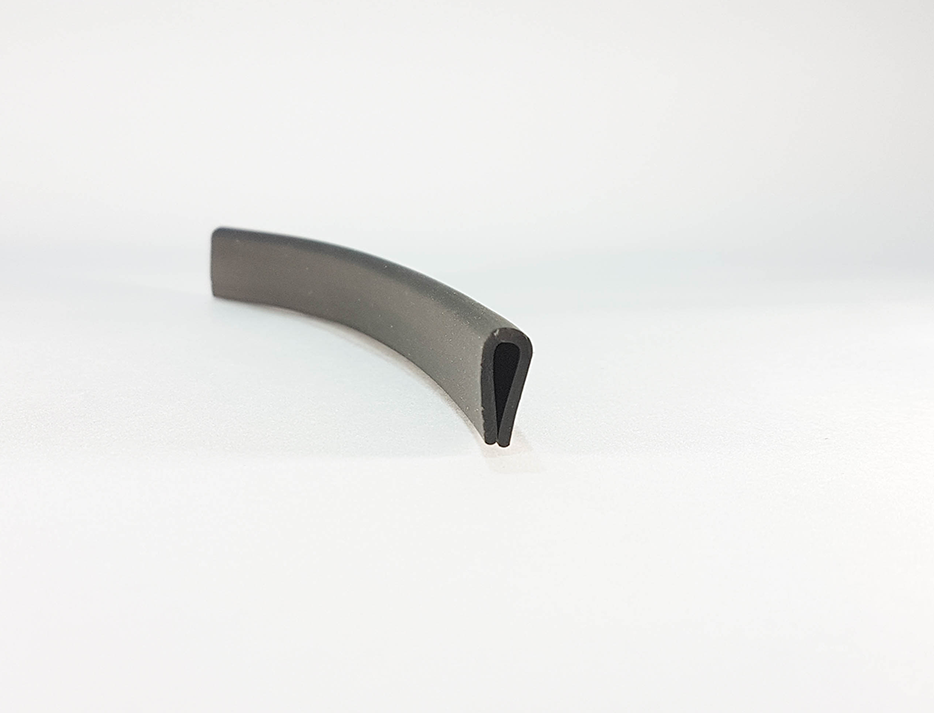

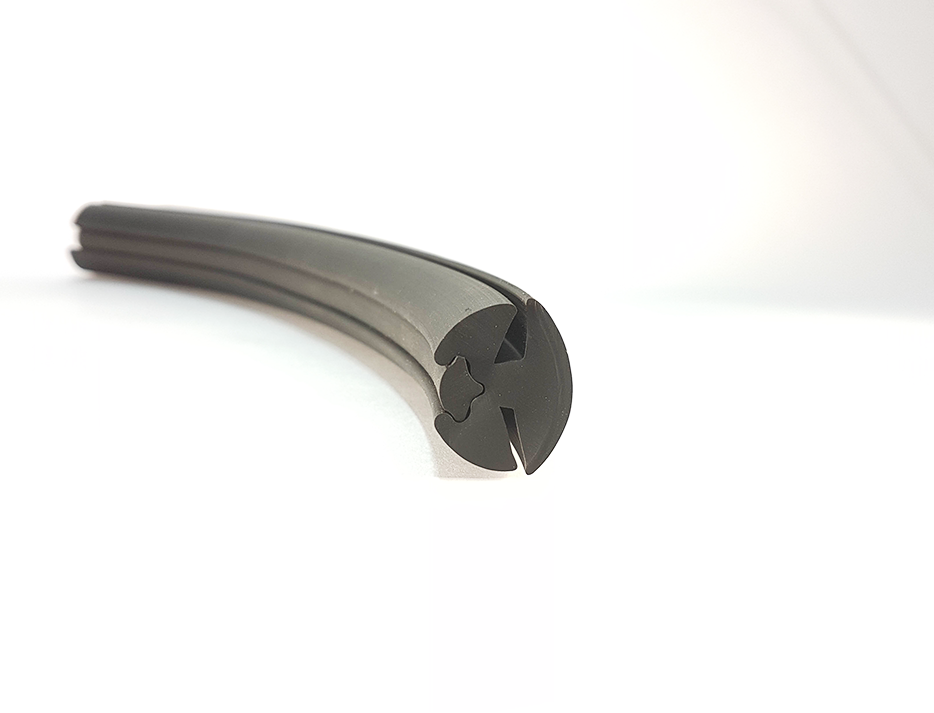

We regularly manufacture extrusions in PVC, upon request alternative materials are available. The common usage for Rubber and PVC extrusions are in applications such as sealing, noise control, vibration and trim.

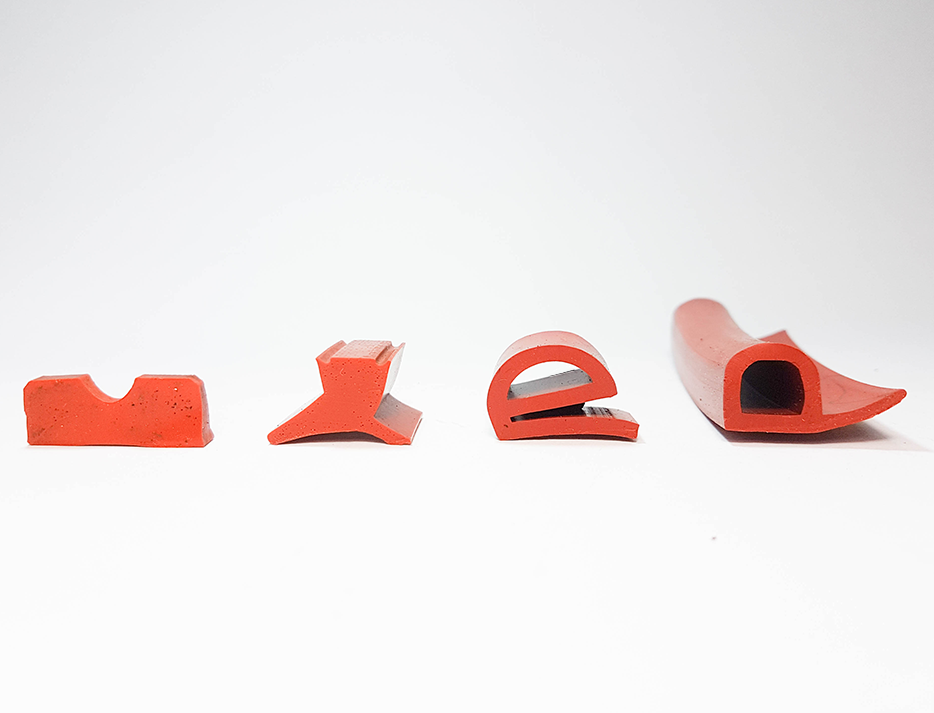

Manufacturing capabilities include complex rubber extrusions, or simple parts. P-shape, D-shape, L-shape, T- Shape, U-channel, tubing, solid rod, and any almost any other custom rubber extrusion shape to meet almost any application.

Your custom rubber extrusion may be coiled for easy shipping and storage or cut in straight lengths to your desired size. When it's time to cure the rubber to its precise shape, we can form tight corners or complex designs.

Extrusion

Bonding

Material

Packaging

Tolerance Table — Rubber Extrusions

The closer tolerance classes outlined below should not be specified unless required to do so by the final application and they should be restricted to the critical dimensions. The closer tolerances demanded, the tighter the control must be exercised when the material is being extruded and hence the higher the cost incurred.

| Extrusion Profiles | Material Specs | App. Process |

|---|---|---|

| Bumper | Mil-Spec | PSA Application |

| Cord | AMS | Chemist and Lab On-Site |

| Window Seal | ROHS | In-House Die Maker |

| Door Seal | Fire Resistant | AS-9100 / ISO9001 |

| Tubing | UV Protection | ITAR Certified |

| Channels | FDA | Boeing Approved |

| Complex Profiles | New Specs | Custom Shapes |

| Extrusion Profiles | Material Specs | App. Process |

|---|---|---|

| U-Channel | BMS1-52 & BMS 1-57 | Pole-Curing |

| P-Shape | BMS1-72 & BMS 1-74 | Hot Bond Splice |

| D-Shape | MIL-PRF-6855 | Cold Bond Splice |

| L-Shape | A-A-59588 | Pole-Curing |

| T-Shape | ASTM | Semi-Clean Room |

| A | BxD | C | Lbs/Ft | Kip/Ft |

|---|---|---|---|---|

| 6 | 3 | 5 | 11.5 | 15.2 |

| 8 | 4 | 8 | 22 | 10 |

| 10 | 5 | 10 | 38 | 8.6 |

| 12 | 6 | 12 | 54 | 7.7 |

| 14 | 7 | 14 | 73 | 4.2 |

| A | B | C | Lbs/Ft | Kip/Ft |

|---|---|---|---|---|

| 6 | 2.5 | 5 | 11.5 | 15.2 |

| 8 | 3 | 8 | 22 | 10 |

| 10 | 4 | 10 | 38 | 8.6 |

| 12 | 5 | 12 | 54 | 7.7 |

| 14 | 6 | 14 | 73 | 4.2 |

| A | B | Lbs/Ft | Kip/Ft |

|---|---|---|---|

| 3 | 1.5 | 3 | 14 |

| 5 | 2.5 | 7 | 10 |

| 6 | 2 | 14 | 11 |

| 8 | 4 | 18.5 | 10 |

| 10 | 5 | 30 | 6.2 |

| 12 | 6 | 42.5 | 5.3 |

| 15 | 7.5 | 68.5 | 3.5 |

| 18 | 9 | 97.5 | 2.9 |

| A | B | C | D | Lbs/Ft | Kip/Ft |

|---|---|---|---|---|---|

| 3 | 1 | 6 | .75 | 4.3 | 25 |

| 4 | 2 | 7.5 | 1 | 10 | 19.5 |

| 6 | 3 | 9 | 1.5 | 15.5 | 13.5 |

| 8 | 4 | 12 | 2 | 30 | 11 |

| 10 | 5 | 15 | 2.5 | 44 | 9 |

| 12 | 6 | 18 | 3 | 58.5 | 6.3 |

| A | B | Lbs/Ft | Kip/Ft |

|---|---|---|---|

| 4.5 | 1.5 | 4.5 | 2 |

| 6 | 2 | 14 | 16 |

| 7 | 2.5 | 22.5 | 12.5 |

| 8 | 3 | 29.5 | 10 |

| 10 | 4 | 45 | 8.5 |

| 12 | 5 | 63 | 7 |

| 14 | 6 | 81 | 3.7 |

| 16 | 7 | 112 | 2.5 |

| A | B | C | D | Lbs/Ft | Kip/Ft |

|---|---|---|---|---|---|

| 3.75 | 2.25 | 4.5 | 2 | 4.5 | 16.7 |

| 6 | 3 | 6.75 | 2.37 | 12.3 | 13.3 |