We have a large inventory of plastic sheets and rods, our engineering capabilities focus around designs for parts produced from machined plastic, like PTFE, PEEK, PA, POM, ACETAL, PAI, PPS, and more.

Garlin is a leading supplier of Plastic Sheets, Plastic Rods, Plastic Tubing and Plastic Films with a massive inventory of high-performance plastic materials.

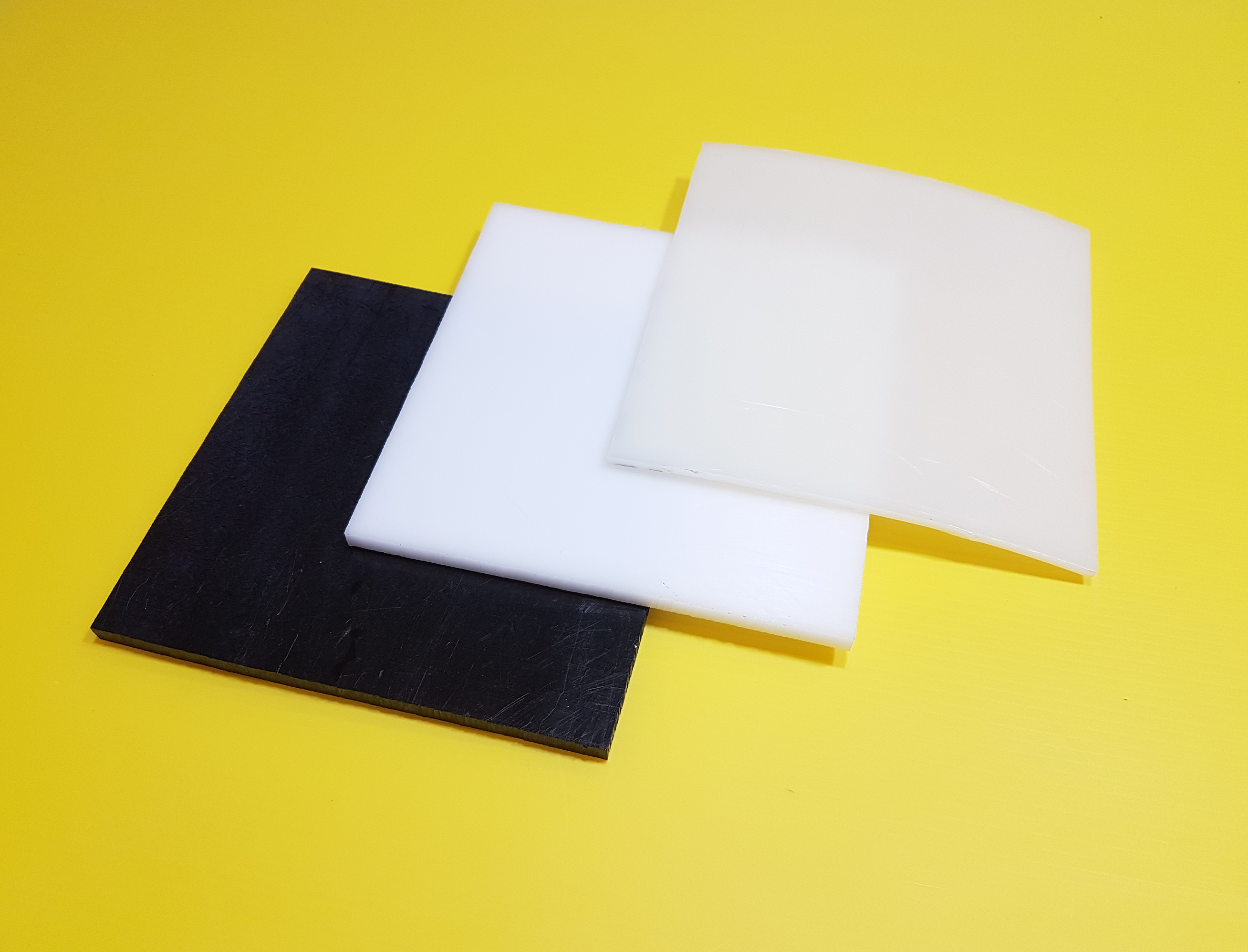

Plastic Sheet

Whether you need one sheet, an odd size, fast turnaround, or delivery Garlin can meet your needs.

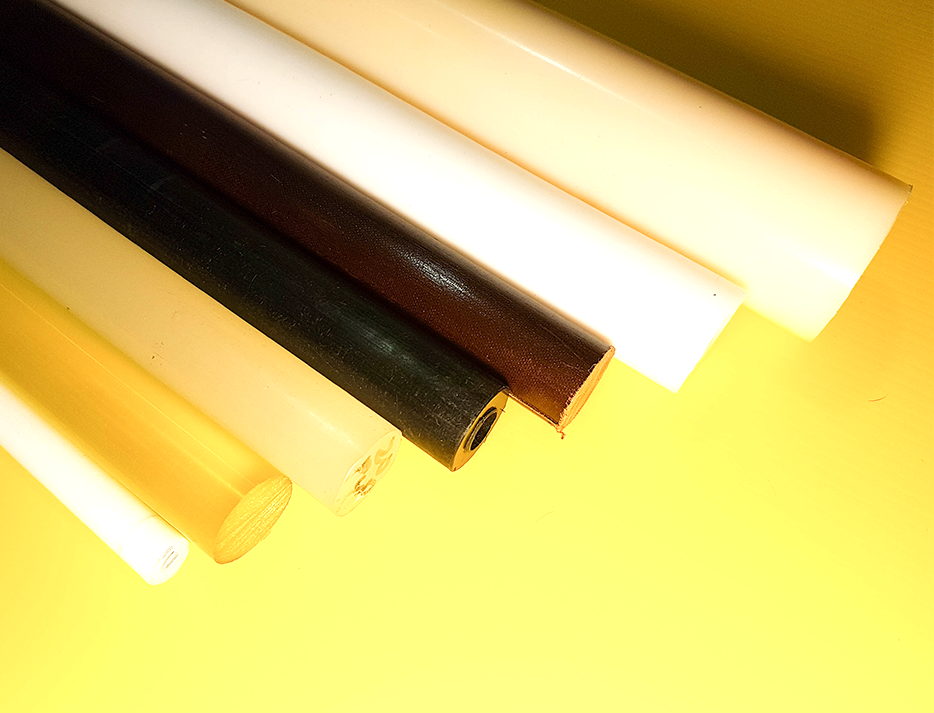

Plastic Rods

Most plastic rods sold by Garlin are used to for cnc manufacturing of bearing, rollers, gears and seals.

Plastic Tubes

Garlin carries a large selection of in stock plastic tubes and we can custom cut to your specifications.

ABS has good chemical and stress-cracking resistance to inorganic salt solutions, alkalies, mineral acids (except strong oxidizing acids), and some mineral, vegetable, and animal oils. ABS is easily machined to close tolerances, is tough, dimensionally stable, and may also be thermoformed. Petroleum-based oils, solvents, and paints SHOULD NOT BE USED, as they will cause the material to craze. ABS is also one of the few non-metallic materials which can be readily electroplated (after an electroless plating surface has been applied using a selective etching process). ABS (Acrylonitrile-Butadiene-Styrene) is a copolymer composed of two copolymers and is one of the most common polymer materials. Styrene and Acrylonitrile form a linear copolymer (SAN) that serves as a matrix. Butadiene and Styrene also form a linear copolymer (BS rubber) which acts as the filler material. The combination of the two copolymers gives ABS an excellent combination of strength, rigidity, and toughness.

ABS (Acrylonitrile-Butadiene-Styrene)

Acrylics offer high light transmittance with a Refractive Index of 1.49 and can be easily heat-formed without loss of optical clarity. Prolonged exposure to moisture, or even total immersion in water, does not significantly affect the mechanical or optical properties of acrylic. Most commercial acrylics have been UV stabilized for good weatherability and resistance prolonged sunlight exposure. Acrylics are unaffected by aqueous solutions of most laboratory chemicals, by detergents, cleaners, dilute inorganic acids, alkalies, and aliphatic hydrocarbons -- however, acrylics are NOT recommended for use with chlorinated or aromatic hydrocarbons, esters, or ketones. Acrylics are easily sawed, drilled, milled, engraved, and finished with sharp carbide-tipped tools. Cut surfaces may be readily sanded and polished. They are also readily bent or thermoformed at low temperature and solvent bonding of properly fitting parts produces a strong, invisible joint. They are available in extruded and/or cast material in sheet, rod and tube forms as well as custom profiles.

Acrylic (PMMA)

Acetal (POM) provides high strength and stiffness coupled with enhanced dimensional stability and ease of machining. As a semi-crystalline material, acetal is also characterized by a low coefficient of friction and good wear properties – especially in wet environments. Because acetal absorbs minimal amounts of moisture, its physical properties remain constant in a variety of environments. Low moisture absorption results in excellent dimensional stability for close-tolerance machined parts. In high moisture or submerged applications, acetal bearings outperform nylon 4 to 1. Acetal is ideally suited for close tolerance mechanical parts and electrical insulators which require strength and stiffness. It also offers resistance to a wide range of chemicals including many solvents.

Acetal Copolymer

Delrin® is a homopolymer acetal (POM) made with DuPont™ Delrin® resin. The Delrin® product line offers enhanced physical property characteristics such as slightly higher tensile and impact strength, better stiffness properties, as well as better fatigue and creep resistance in comparison to copolymer Acetal because of its crystalline structure. However, Delrin® may contain a low density center (known as "centerline porosity"), especially in large cross-sections. Delrin® homopolymer acetal also gives slightly less chemical resistance than copolymer Acetal. Delrin® 150 is a standard general purpose, unfilled homopolymer Acetal extrusion grade for stock shapes. This grade has the best impact toughness of all unfilled Delrin® products. Delrin® 150 SA was discontinued in 2003 & replaced by Delrin® 150.

Delrin® Acetal Homopolyer

Nylon’s toughness, low coefficient of friction and good abrasion resistance make it an ideal replacement for a wide variety of materials from metal to rubber. It weighs only 1/8 as much as bronze. Using nylon reduces lubrication requirements, eliminates galling, corrosion and pilferage problems, and improves wear resistance and sound dampening characteristics. Nylon has a proven record of outstanding service in a multitude of parts for such diverse fields as paper, textiles, electronics, construction, mining, metalworking, aircraft, food and material handling.

Nylon

PEEK grades offer chemical and hydrolysis resistance similar to PPS, but can operate at higher temperatures. PEEK 1000 offers steam and wear resistance, while carbon-reinforced PEEK provides excellent wear capabilities. Our latest grade, PEEK HPV, offers outstanding bearing performance. PEEK can be used continuously to 480°F (250°C) and in hot water or steam without permanent loss in physical properties. For hostile environments, PEEK is a high strength alternative to fluoropolymers. PEEK carries a V-O flammability rating and exhibits very low smoke and toxic gas emission when exposed to flame.

PEEK Unfilled

PET-P is an unreinforced, semi-crystalline thermoplastic polyester, also known as polyethylene terephthalate (PET-P). It is characterized as having the best dimensional stability coupled with excellent wear resistance, a low coefficient of friction, high strength, and resistance to moderately acidic solutions. PET-P’s properties make it especially suitable for the manufacture of precision mechanical parts which are capable of sustaining high loads and enduring wear conditions. PET’s continuous service temperature is 210°F (100°C) and its melting point is almost 150°F higher than acetals. It retains significantly more of its original strength up to 180°F (85°C) than nylon or acetal.

PET-P

HYZOD/Makrolon polycarbonate sheet is as clear as glass and 250 times stronger. It’s also 30 times stronger than an acrylic sheet – offering a margin of safety that no other clear glazing material can beat. With its inherent design flexibility, HYZOD/Makrolon can be cut or cold-formed on site during installation without the pre-forming and fabrication associated with glass or acrylic. It is lightweight and requires less structural support compared to all-glass systems, saving additional time and labor costs. Of course, its durability and energy efficiency add up to long-term cost savings too. Sheet, Rod & Tube (colors available)

Polycarbonate

Polyethylenes are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance, and a wide range of properties (due to differences in length of the polymer chain). Polyethylenes are easy to distinguish from other plastics because they float in water. Polyethylenes provide good resistance to organic solvents, degreasing agents and electrolytic attack. They have higher impact strength, but lower working temperatures and tensile strengths than polypropylene. They are light in weight, resistant to staining, and have low moisture absorption rates.

Polyethylene

Polypropylene provides excellent resistance to organic solvents, degreasing agents and electrolytic attack. It has a lower impact strength, but its working temperatures and tensile strength are superior to low or high density polyethylene. It is light in weight, resistant to staining, and has a low moisture absorption rate. This is a tough, heat-resistant, semi-rigid material, ideal for the transfer of hot liquids or gases. It is recommended for vacuum systems and where higher heats and pressures are encountered. It has excellent resistance to acids and alkalines, but poor resistance to aromatic, aliphatic and chlorinated solvents.

Polypropylene

PSU 1000 Polysulfone (PSU) is an amber semi-transparent, heat-resistant, high performance engineering thermoplastic. It offers excellent mechanical, electrical and improved chemical resistance properties relative to polycarbonate. Polysulfone’s properties remain relatively consistent over a broad temperature range, from –150°F to 300°F (-100°C to 100°C). PSU 1000 Polysulfone offers high chemical resistance to acidic and salt solutions, and good resistance to detergents, hot water and steam. In addition, polysulfone has excellent radiation stability, and offers low ionic impurity levels. PSU 1000 Polysulfone often replaces polycarbonate when higher temperatures, improved chemical resistance or autoclavability is required . It is commonly used for analytical instrumentation, medical devices and semiconductor process equipment components.

Polysulfone – PSU

PPS (polyphenylene sulfide) products offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 392°F (200°C) and offer inertness to steam, strong bases, fuels and acids. Minimal moisture absorption and a very low coefficient of linear thermal expansion, combined with Quadrant’s proprietary stress relieving processes, make these PPS products ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant.

PPS

PVC is the most widely used member of the vinyl family. PVC offers excellent corrosion and weather resistance, has a high strength-to-weight ratio, and is a good electrical and thermal insulator. PVC is also self-extinguishing per UL flammability tests. PVC may be used to temperatures of 140°F (60°C) and is readily available in sheets, rods, and tubing. PVC may be cemented, welded, machined, bent and shaped readily. Available in Sheet, Rod, Hex, and Angle.

PVC

PVDF (Kynar) is a specialty plastic material in the fluoropolymer family. It is used generally in applications requiring the highest purity, strength, and resistance to solvents, acids, and bases. Excellent performance in many applications up to 300°F (149°C) cause this material to be commonly used in the chemical, semiconductor, medical and defense industries. Available in Sheet & Rod.

PVDF

Teflon™ mechanical properties are low compared to other plastics, but its properties remain at a useful level over a wide temperature range of of -100°F to +400°F (-73°C to 204°C). Mechanical properties are often enhanced by adding fillers (see paragraph below). It has excellent thermal and electrical insulation properties and a low coefficient of friction. PTFE is very dense and cannot be melt processed -- it must be compressed and sintered to form useful shapes. Available in Sheet, Rod & Tube.

Teflon™ – PTFE

UHMW sets the standards for engineering polymers with a unique combination of wear and corrosion resistance, low-friction surface and impact strength. It retains key physical properties to -30°C. UHMW is resistant to chemical attack and moisture absorption. UHMW meets FDA, USDA, and 3-A Dairy guidelines for food processing and handling. Whether you’re moving grain, pharmaceuticals, pizza dough or frozen poultry, UHMW material predictably moves materials and products. An excellent general purpose material, UHMW is a cost-effective solution to your food handling applications. Available in Sheet, Rod & Tube.

UHMW

Ultem™ commonly is machined into parts for reusable medical devices, analytical instrumentation, electrical/electronic insulators (including many semiconductor process components) and a variety of structural components requiring high strength and rigidity at elevated temperatures.

Ultem™