Garlin's Jaw Couplings are offered in a large variety of stock bore/keyway combinations. These couplings require no lubrication and provide reliable service for light, medium, and heavy-duty electric motors and internal combustion power transmission applications.

Applications include power transmission to industrial equipment such as pumps, gearboxes, compressors, blowers, mixers, and conveyors. Garlin's couplings are available in many sizes from a minimum torque rating of 3.5 in–lbs (0.4 Nm) to a maximum torque rating of > 150,000 in–lbs (11,300 Nm) and a bore range of .125 inches (4.45 mm) to >3 inches (76 mm). Garlin’s standard bores include AGMA, SAE, and DIN bore/keyway and spline bore combinations.

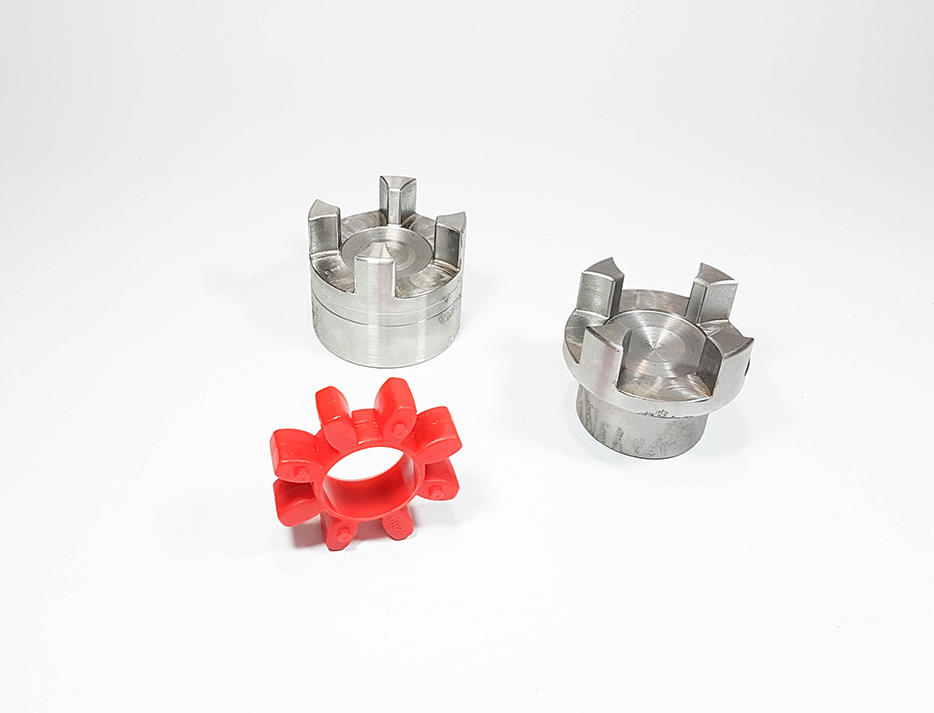

Garlin's Jaw Type couplings generally consist of two hubs (available in aluminum and mild steel), and an elastomer element, known as a spider or cushion (materials available include NBR Rubber, Urethane, and Bronze).

Jaw Coupling Product Range:

L Type – Mild Steel:

- Industry’s standard shaft coupling

- Fail-safe (will still perform if elastomeric “spider” fails)

AL Type – Aluminum:

- Lightweight aluminum version of the standard shaft coupling

- Corrosion resistant (finished bores passivated for added protection)

C Type – High Torque:

- Greater torque and bore capacity (compared to L type)

- Fail-safe; plus radially removable elastomeric cushions

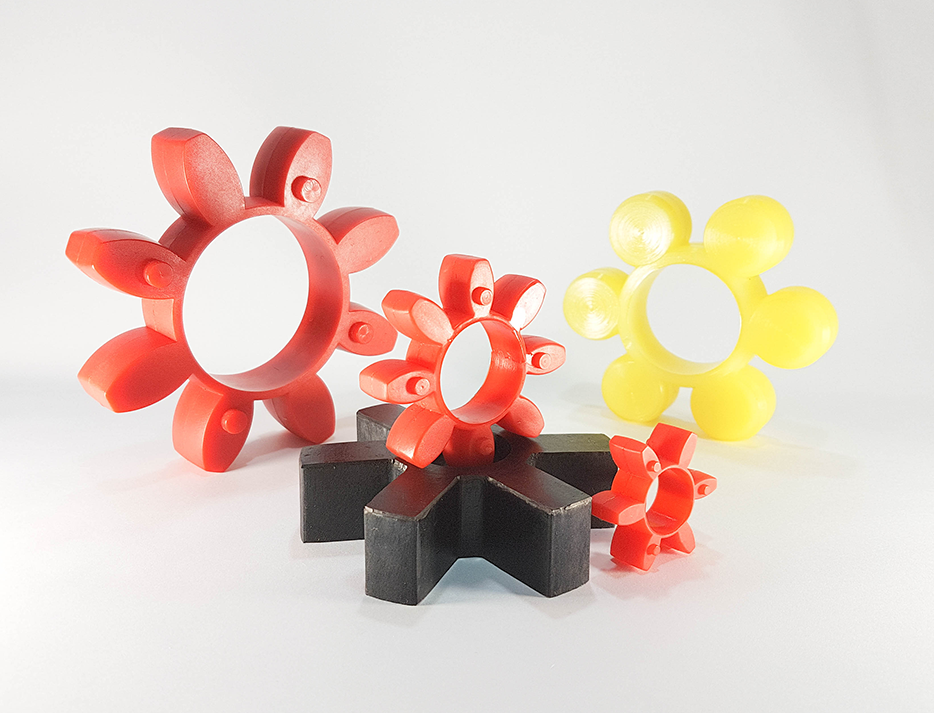

Jaw Coupling Spiders

Garlin offers stand-alone replacement elements of the jaw coupling elastomer and "spider" shaped part which press fits between the two hubs. The jaw from each hub fits alternately with the lobes of the spider. The curved jaws of the hubs reduce deformation of the spider to maintain the zero-backlash fit.

Allowing for misalignment between shafts, these spiders offer high torque and excellent shock-dampening capabilities. They can hold up against dirt, sand, grease, oil, and moisture, with no lubrication required. The elastomer of the spider can be made in different hardnesses, which allows the user to customise the coupling so that it absorbs more or less vibration.