Garlin’s gasketing is offered in a wide range of materials, including PTFE, compressed fiber gasketing, flexible graphite sheet, Temperature gasketing and high-performance rubber sheet products.

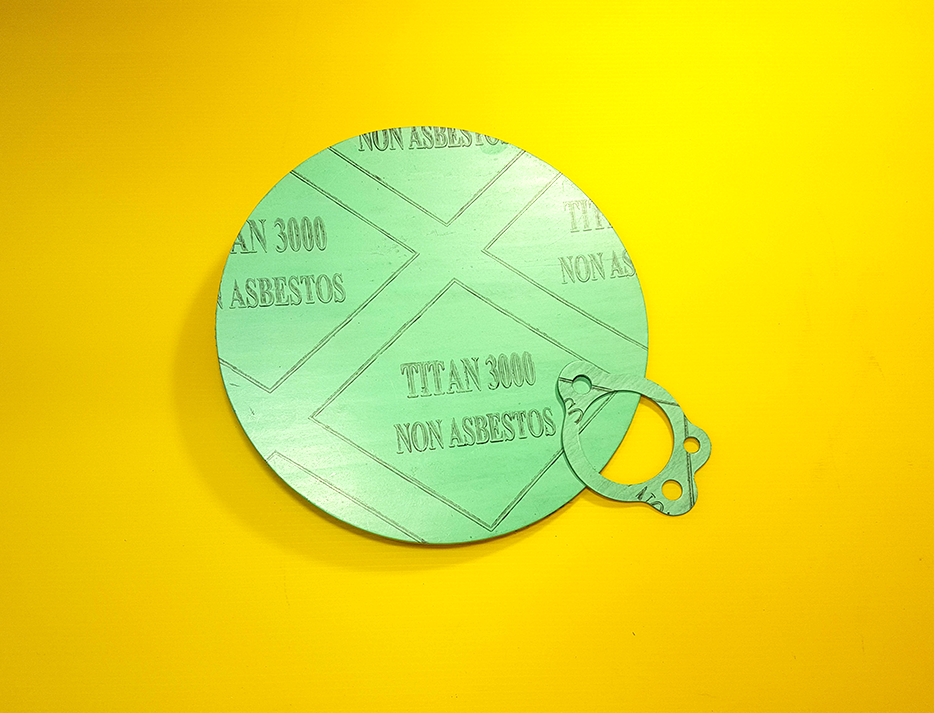

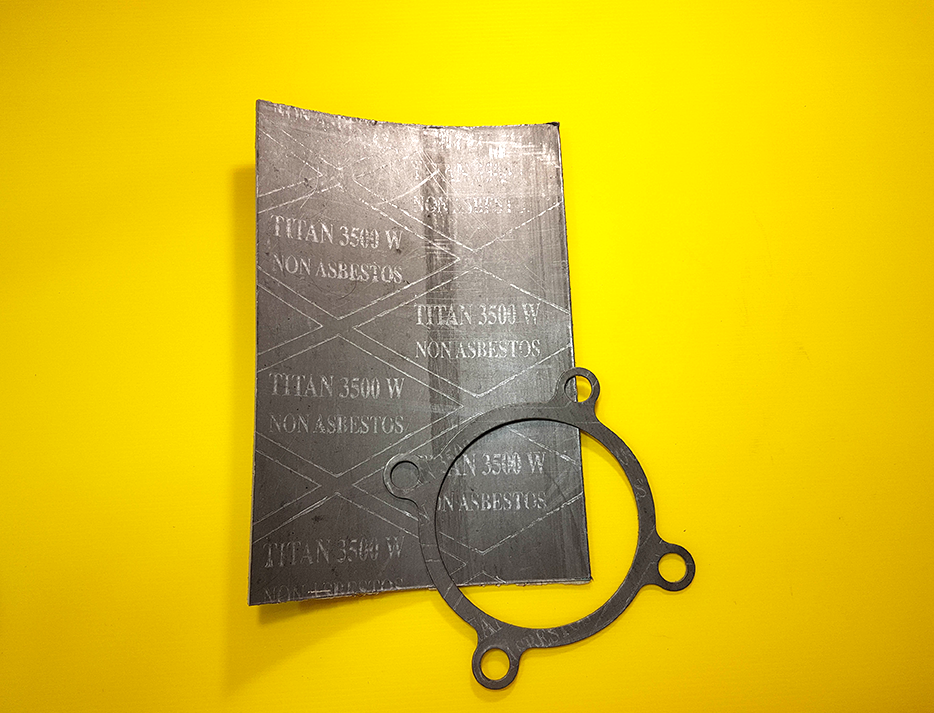

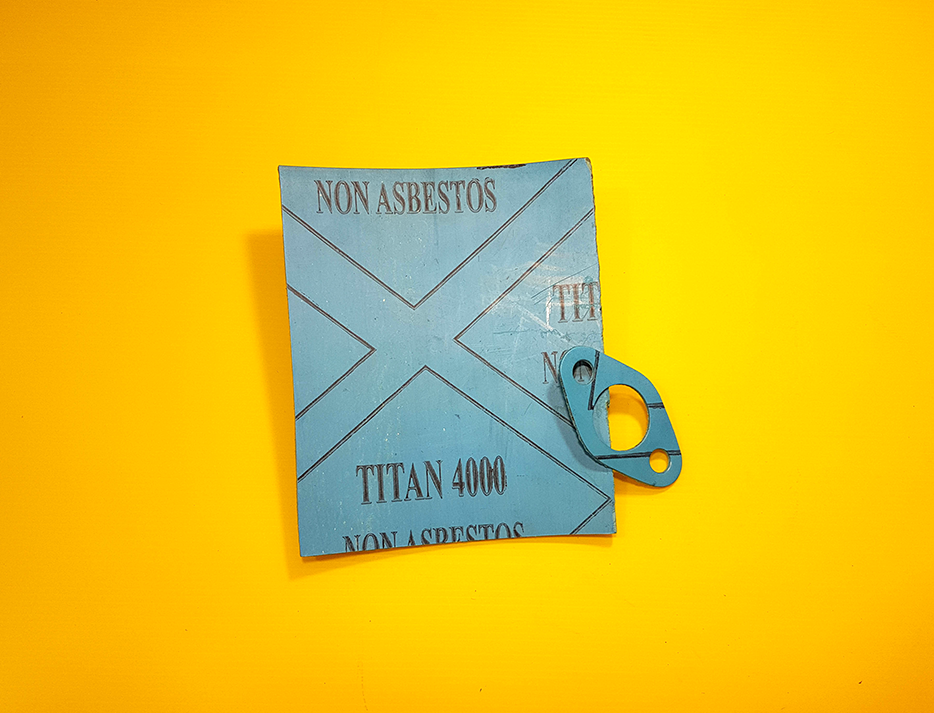

Fiber Gasketing:

Compressed fiber gasketing materials are manufactured using a technique referred to as the High-Pressure Sheet process (HPS). Products are made with non-VOC solvent which is environmentally friendly.

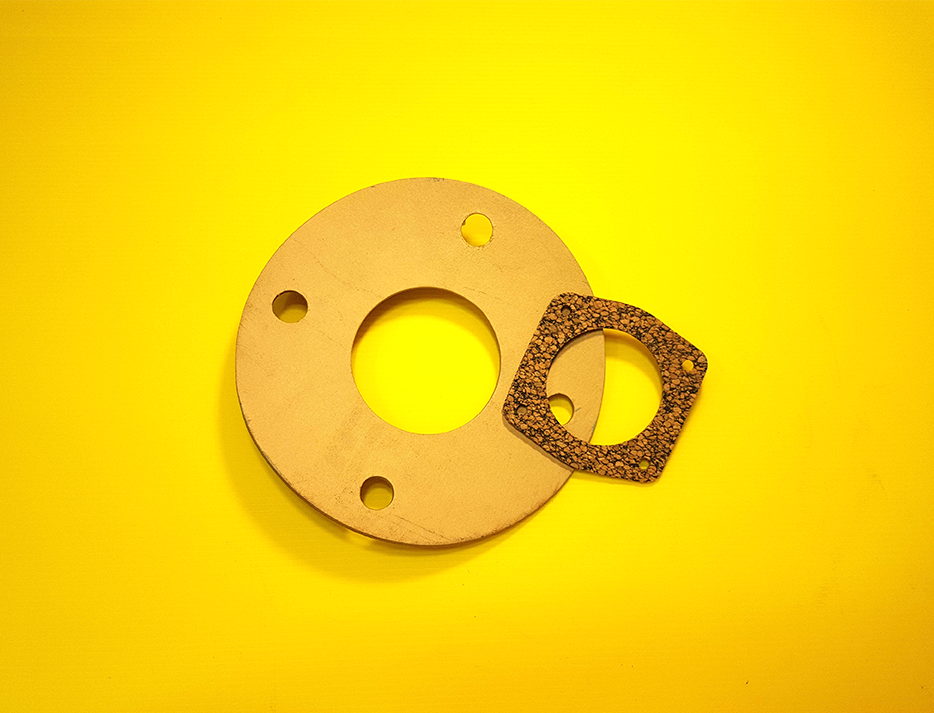

PTFE Gasketing:

PTFE Gasketing is a proven product that is known throughout industry as the material of choice for severe chemical services. In addition, gasket size availability is flexible, as the product can be thermally bonded.

Asbestos-free sealing materials able to cover a wide range of applications. Materials are manufactured extensive levels of quality control, are easy to cut, handle and fit.

High temperature sealing applications, such as waste gas and engine operations, require a gasket material that requires a long-term seal at temperatures > 500°C.

PTFE gaskets provide chemical resistance making it suitable for sealing virtually any chemical medium. PTFE based sealing materials are the go to option for chemical resistance.

Expanded Teflon Sheet:

Garlin's expanded PTFE requires low stress to seal, making it ideal for fragile or lightly loaded flange assemblies such as those made from FRP, aluminum, graphite and glass-lined steel. The extremely high tensile strength of the PTFE sheet gaskets also protects against overcompression. Regularly installed on pipe flanges these gaskets can be used in applications up to 3,000 psi (200 bar), effectively sealing between flanges that are rough or damaged. A positive, reliable seal is routinely achieved on all flange materials and in all processing conditions under 600° F (315° C).

Joint Sealant Tape:

Garlin’s joint sealant tape is made of solid PTFE. This joint sealant tape can withstand a wide range of chemicals and meets FDA regulations. The sealant tape is easy to cut and form, and the adhesive backing makes it easy to install on narrow and hard-to-reach flanges.